The Prediction: By 2025 50% of all manufacturers will have extended visibility to Tier-3 supply

Technologies related to control towers, visibility and machine learning are in the spotlight when it comes to supply chain planning. Supply Chain Media asked a number of international supply chain directors for their reactions to some well-known analyst firms’ predictions about this topic.

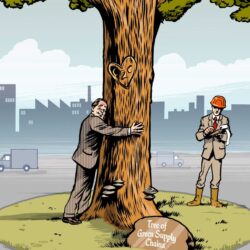

The Prediction: By 2025, according to IDC, 50% of all manufacturers will have extended visibility to Tier-3 supply, enabling more agile supply chains and a 50% reduction in the impact of supply-side disruptions.

Vineet Khanna, Senior Vice President, Global Head of Supply Chain at Nestlé:

“Extended upstream visibility up to Tier 3 is crucial to improve resilience. Once again, supply disruptions can be managed not just by visibility, but also by building flexibility: flexibility in sourcing, supply base as well as product formulation. Equally, it requires a shift in the nature of relationships with suppliers: from purely extracting value to building a reliable partnership beyond cost into resilience, flexibility and trust. Considering these challenges, while every company is making progress, many companies may not be able to sustain their progress once the urgency of the current crises fades a little and the cost of inflation starts to bite deeply.”

Sami Naffakh, Chief Supply Officer, Member of the Group Executive Committee at Reckitt:

“Visibility into Tier-2 and Tier-3 supply is essential to guarantee both resilience/continuity of supply and to drive the necessary improvements in sustainable and responsible sourcing. Nonetheless, given the complexity of some supply chains – typically those using agriculturally derived ingredients – I am doubtful things will go as fast as predicted by IDC.”

“Visibility into Tier-2 and Tier-3 supply is essential to guarantee both resilience/continuity of supply and to drive the necessary improvements in sustainable and responsible sourcing. Nonetheless, given the complexity of some supply chains – typically those using agriculturally derived ingredients – I am doubtful things will go as fast as predicted by IDC.”

Freek van Iersel, Supply Chain Director Electronics EMEA at Signify:

“The drive for more insight is certainly there. And I do believe it will come or is already being realized. But a 50% reduction in the impact of supply-side disruptions seems a lot. What we see in practice is that the improved visibility gives us more time to react by releasing an alternative component, buying from another supplier or on the open market (via spot buys). This limits the impact on our final output, but more insight into a supplier does not necessarily mean that the specific supplier will deliver better.”

Thomas Panzer, SVP – Head Supply Chain Management at Bayer AG:

“I support the statement that all manufacturers are undertaking substantial efforts to increase the visibility down to Tier-3 suppliers. However, seeing that this objective has already been around for some years and seeing the real progress versus the ever-increasing complexity of networks in a more volatile environment, I believe that we are having a hard time to even catch up with, let alone to effectively reduce the impact of supply-side disruptions. Our challenge will be to avoid a more severe disruption in the future.”

“I support the statement that all manufacturers are undertaking substantial efforts to increase the visibility down to Tier-3 suppliers. However, seeing that this objective has already been around for some years and seeing the real progress versus the ever-increasing complexity of networks in a more volatile environment, I believe that we are having a hard time to even catch up with, let alone to effectively reduce the impact of supply-side disruptions. Our challenge will be to avoid a more severe disruption in the future.”

Sikko Zoer, Vice President Global Supply Chain, Distribution & Logistics at Medtronic:

“My expectation is that manufacturers will indeed continue to invest in upstream visibility and even go beyond Tier-3 suppliers. This will certainly lead to other more flexible, but also more robust supply chains and therefore less disruption. Whether this will lead to a 50% reduction will depend mainly on the will and the possibilities to take the necessary actions and make the necessary investments based on improved visibility and insights.”

Pieter Aarts, Head of Global Supply Chain & Inventory at Kaspersky:

“This percentage is of course debatable, but there will certainly be more insight into upstream suppliers. I don’t know if this will necessarily provide flexibility – that also requires the move to multiple sourcing – but insight does provide the basis for more robust planning and proactivity. Compliance (environment, working conditions, etc.) will probably be a more important driver of upstream insight.”

“This percentage is of course debatable, but there will certainly be more insight into upstream suppliers. I don’t know if this will necessarily provide flexibility – that also requires the move to multiple sourcing – but insight does provide the basis for more robust planning and proactivity. Compliance (environment, working conditions, etc.) will probably be a more important driver of upstream insight.”