The Prediction: By 2023 fewer than 5% of control tower-like deployments will fulfil their E2E potential

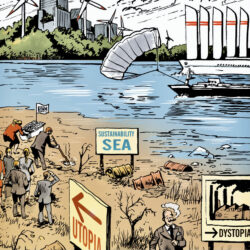

Technologies related to control towers, visibility and machine learning are in the spotlight when it comes to supply chain planning. Supply Chain Media asked a number of international supply chain directors for their reactions to some well-known analyst firms’ predictions about this topic.

The Prediction: By 2023, according to Gartner, fewer than 5% of control tower-like deployments will fulfil their end-to-end (E2E) potential due to mindset and cultural obstacles. However, IDC predicts that, by 2024, 50% of manufacturers using supply chain orchestration control towers will have integrated supply chain digital twins for a 10% improvement in innovation delivery and disruption avoidance.

Vineet Khanna, Senior Vice President, Global Head of Supply Chain at Nestlé:

“There are two crucial questions. One is the definition of E2E, and the other is the ability to connect the flow of information – and more importantly the flow of insights and intelligence – among different pieces of technology deployed in the E2E value chain. For true supply chain orchestration, linking internal data (and, very importantly, external data) to drive visibility and responsiveness is a significant challenge. That’s why we hear the expression ‘data-rich but insight-poor’. For true orchestration, the organization must be able to connect core systems, integration layers, data platforms and analytics. Considering these, I believe only a handful of the companies will achieve true E2E supply chain orchestration. However, as they say, ‘perfection is the enemy of progress’, so there is a strong business case for making progress in a step-by-step manner and focusing on highest-value cases first rather than aiming for perfection. For example, investing in demand sensing by itself will generate value and then it can be linked with responsive supply planning as a first step.”

“There are two crucial questions. One is the definition of E2E, and the other is the ability to connect the flow of information – and more importantly the flow of insights and intelligence – among different pieces of technology deployed in the E2E value chain. For true supply chain orchestration, linking internal data (and, very importantly, external data) to drive visibility and responsiveness is a significant challenge. That’s why we hear the expression ‘data-rich but insight-poor’. For true orchestration, the organization must be able to connect core systems, integration layers, data platforms and analytics. Considering these, I believe only a handful of the companies will achieve true E2E supply chain orchestration. However, as they say, ‘perfection is the enemy of progress’, so there is a strong business case for making progress in a step-by-step manner and focusing on highest-value cases first rather than aiming for perfection. For example, investing in demand sensing by itself will generate value and then it can be linked with responsive supply planning as a first step.”

Sami Naffakh, Chief Supply Officer, Member of the Group Executive Committee at Reckitt:

“I agree with Gartner that whereas E2E integrated planning systems and control towers are essential enablers, if the right culture, mindset and capabilities are not in place they are likely to fail in delivering on their expected objectives. This is why the change management should primarily focus on these elements, rather than the technical side of things.”

Thomas Panzer, SVP – Head Supply Chain Management at Bayer AG:

“I’m certainly not able to judge the number. However, I fully subscribe to the fact that a lot of control towers do not reach their full potential. The major obstacle is the openness of all participants in an E2E supply chain network to allow full transparency by sharing all information. This limits the potential of these control towers. I doubt that we will see such a high share of digital twins across the industry with such a high benefit rate of 10% so soon. It takes quite some time to set up digital twins which go beyond one-time simulation approaches and are used in the day-to-day operational planning activities. We have good experience with our pilot cases delivering impressive results, but scaling up to a larger network takes time and significant resources. So, my assumption is that it will take longer to reach 50%.”

Freek van Iersel, Supply Chain Director Electronics EMEA at Signify:

“I agree with both statements. I see the importance of control tower-like systems growing due to the amount of information available on the one hand and the lessons learned from the pandemic on the other. Likewise, the use of digital twins will grow and contribute to improving visibility and reducing disruptions. But I also believe that the full potential will not be reached. It takes a long time before a new implementation is fully embraced and utilized. Often you see that the current needs are covered first, and only at a later stage does it become apparent what a control tower or similar implementation actually has to offer.”

“I agree with both statements. I see the importance of control tower-like systems growing due to the amount of information available on the one hand and the lessons learned from the pandemic on the other. Likewise, the use of digital twins will grow and contribute to improving visibility and reducing disruptions. But I also believe that the full potential will not be reached. It takes a long time before a new implementation is fully embraced and utilized. Often you see that the current needs are covered first, and only at a later stage does it become apparent what a control tower or similar implementation actually has to offer.”

Olav Gribnau, Supply Chain Director Northern Europe at Hero Group:

“As far as Gartner’s vision is concerned, this could actually be true. Especially companies that have to make a transition from local control and management (control from various smaller entities) to a broader control from a control tower have to go through a major cultural and also leadership change. Don’t forget that most leaders of these companies grew up with the traditional way of working. Management from a control tower really is a different game that the leadership of the company also has to learn to play. And as everyone knows: change only comes from changing the behaviour of the leaders. In short: a control tower is not something you put in place as a ‘big bang’, but is something that has to grow from a different way of managing. Regarding IDC’s vision, the question is whether it is a complete digital twin or just a reflection of part of the company – and of course whether it is a real-time digital twin. I strongly believe that companies will realize digital twins in partial areas. Maybe not quite the real-time kind, but certainly digital twins with only a slight lag to reality. I also believe that, in those areas where they are introduced, significant improvements will be realized.”

Sikko Zoer, Vice President Global Supply Chain, Distribution & Logistics at Medtronic:

“A major challenge with control tower implementations is indeed the fulfilment of a number of critical success factors. A control tower is not a stand-alone system, but an integral part of an ecosystem that consists of other systems both within the boundaries of the own organization (e.g. ERP, APS, etc.), but also external systems (e.g. from transporters). In order to make optimal use of a control tower within such an ecosystem, there must be an integrated system architecture, along with an integrated and accurate data model and a well-defined governance model that captures the initial definitions, but also proactively identifies changes and ensures unambiguous processing. That demands a lot from an organization. Processes must be unambiguously defined with clear roles and responsibilities. But paradoxically, it also requires a different mindset and culture. On the one hand, as an organization you have to remain flexible within a more standardized environment. I call that ‘standardized flexibility’. On the other hand, you must become agile in thought and action. This also means that decision-making powers must be placed lower down in the organization. In addition, the large amount of data and information that needs to be processed means that technology (AI, ML, etc.) will be used much more within control tower environments to identify events, but also to make decisions. In other words, a level of trust must be established in the organization and in the technology. This requires a change in the thinking and actions of managers, but also a different profile of planners, analysts, etc.”

“A major challenge with control tower implementations is indeed the fulfilment of a number of critical success factors. A control tower is not a stand-alone system, but an integral part of an ecosystem that consists of other systems both within the boundaries of the own organization (e.g. ERP, APS, etc.), but also external systems (e.g. from transporters). In order to make optimal use of a control tower within such an ecosystem, there must be an integrated system architecture, along with an integrated and accurate data model and a well-defined governance model that captures the initial definitions, but also proactively identifies changes and ensures unambiguous processing. That demands a lot from an organization. Processes must be unambiguously defined with clear roles and responsibilities. But paradoxically, it also requires a different mindset and culture. On the one hand, as an organization you have to remain flexible within a more standardized environment. I call that ‘standardized flexibility’. On the other hand, you must become agile in thought and action. This also means that decision-making powers must be placed lower down in the organization. In addition, the large amount of data and information that needs to be processed means that technology (AI, ML, etc.) will be used much more within control tower environments to identify events, but also to make decisions. In other words, a level of trust must be established in the organization and in the technology. This requires a change in the thinking and actions of managers, but also a different profile of planners, analysts, etc.”