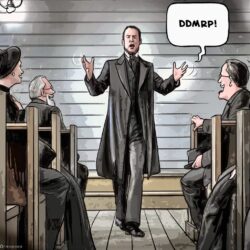

Beware of dogmatic DDMRP

The term ‘Demand-Driven Material Requirements Planning’ (DDMRP) has been around since 2011 but has been attracting particular attention in the past couple of years. It makes some grand promises: higher service levels, 30-40% inventory reductions, shorter lead times (up to 80% faster) and minimal costs. Are the windows of your Supply Chain department steaming up yet?!

By Hans van der Drift

DDMRP is based on the fact that variability is bad for the performance of a system such as a production line or distribution system. Variability is reduced by the intelligent use of inventory buffers at key junctions in the supply chain. That’s smart, because everyone knows that the bullwhip effect can soon develop in classically managed multi-echelon systems.

DDMRP has been publicized by the Demand Driven Institute through its own conferences, renowned gurus as sponsors and software certifications. The founders of the institute have been preaching endlessly to anyone who will listen. They’ve done an impressive job, yet the process has still only been embraced on a very limited scale in the supply chain world. So is it just another hype that will blow over? That would be a shame and also unnecessary, because DDMRP’s current lack of real success is due to two demonstrable reasons.

Problem 1: dogmatism

DDMRP advocates sing its praises as if it were almost a religion, often to the point of dogmatism. That is wonderful if you’re already one of the converted, but less so if you have a more wait-and-see attitude. Thanks to DDMRP, for instance, you’re “no longer dependent on unreliable forecasts”. That’s great news of course, apart from the fact that the term ‘Average Daily Usage’ (ADU) suddenly appears. Can anyone tell me how that differs from a forecast that’s simply the average of the previous periods? And if we then also start to manipulate that ADU in Demand-Driven Sales & Operations Planning to manage pre-builds, for example, then I slowly feel the atheist inside me awakening…

Problem 2: applicability

Nobody is claiming that DDMRP is right for every situation, but there is a strong suggestion that it is very widely applicable. But does it also work in job shops, chemical production or the pharmaceutical industry? That would be fantastic for a simple technique that you can implement in five steps including certified standard software. I’m gradually beginning to lose faith. Surely we can’t just cast aside 50 years of differentiated supply chain theory so easily?

And that is indeed not the case. DDMRP is an interesting process based on a couple of smart principles that can produce impressive results in specific situations. The demand can vary, for example, but the average must remain fairly constant in order for the ADU to be accurate. If it isn’t, manual intervention will soon be necessary and the dogmatism will come under pressure. Besides that, DDMRP doesn’t work with capacity inventory for example. That’s a shame, because that is particularly effective at keeping your expensive production lines running at a high capacity utilization rate. Surely we’re not just going to stop due to smart ‘levelling’?

Cherry picking

So what is the right approach? As you probably expected, the solution is less ‘standard’ than the preachers would have us believe. First, start by asking yourself whether you are actually suffering from the problems that DDMRP can solve. Then, check whether standard DDMRP could work in your specific situation. If the answer is ‘yes’ in both cases, you can set to work with it. Bingo!

In a great many cases, however, one of the two answers will be more of a ‘maybe’. Don’t panic – although this will now require creativity and insight into the dynamic behaviour of supply chains. Needless to say, the first step must be to clearly define the objectives: which problem do we really want to solve? Then, by logically combining elements from Demand-Driven Supply Chain Management with its variants and with more traditional techniques such as capacity inventory, workload management, sprint times and so on, you can succeed in finding solutions for a huge variety of supply chains in virtually all industry segments. In other words, it delivers on its promise, just not in such a standardized way as is sometimes implied. The world’s simply not as clear-cut as that.

Conclusions

Demand-Driven Supply Chain Management, supported by dynamic buffers, is extremely powerful and widely applicable. The specific DDMRP variant is standardized and simpler, but therefore doesn’t work in every situation. So don’t be lured into choosing a dogmatic solution for something that might not even be a problem for you. Instead, you should cherry pick to combine the best solution for your situation – the one that solves your particular problem!

Hans van der Drift is a partner at Involvation