The Wheel of Five for Supply Chain Management: Absorb variation with stock and time

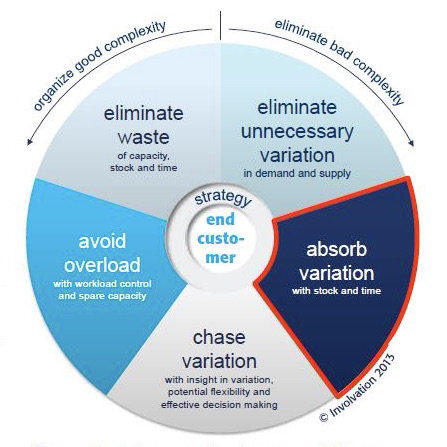

To help organizations recognize and effectively deal with good and bad variability, Involvation has developed the Wheel of Five for Supply Chain Management. This is Part 2 in a series of five.

Of the five principles in the Wheel of Five, ‘Absorb variation with stock and/or time’ is possibly the one that is most commonly ignored. Rather than being absorbed as quickly as possible to reduce the upstream or downstream disruption it causes, variation actually tends to be passed on and is intensified each time (bullwhip effect). Although this is often unintentional and even unconscious, the consequences are significant.

Unlike capacity, stock and time make it possible to absorb variation so you can avoid this by freeing up time and/or stock and utilizing them differently. For example, you can add to stock when it is quiet and supply from stock when it is busy. Thanks to this so-called capacity stock, production can remain at a steady level despite variation in demand.

Now, you might be thinking that this will result in more inventory and/or longer lead times. In fact, the opposite is true. Sufficient stock and time is often available, but just not being used effectively.

Unreliable

In fact, GKN Fokker Hoogeveen proved this by introducing smart inventory buffers. Until recently, the company’s composite factory suffered from long, unreliable lead times and lots of work in progress (WIP). Analysis revealed that this was largely due to the use of Material Requirements Planning (MRP) for operational planning purposes. MRP relies on the Master Production Schedule (MPS) – and the lead time and processing time – being reliable, but that wasn’t the case at GKN Fokker Hoogeveen. This resulted in a backlog of orders and uncertainty about the scheduled starting times. The lack of clear priorities resulted in long and unreliable lead times and a high volume of WIP.

However, the actual demand was relatively constant. Therefore, it was soon agreed that the priority should simply be determined based on the remaining stock and the remaining production time. The lower the remaining stock and the longer the remaining production time, the higher the priority should be and vice versa.

Colour-coded orders

To add extra value to the relative priorities, orders are colour-coded based on the current situation: red for ‘must be done now’, orange for ‘must be done soon’ and green for ‘not yet necessary, but can be done if there is time’. Red orders are fast-tracked into production as quickly as possible, with little to no delay. Thanks to the green orders, Production always has something to do even if there is a lull in sales or if it is ahead of schedule.

Some orders are colour-coded blue, which means they may not yet go into production (even if the MRP due date has passed) because the company already has more than enough stock of the item in question. “Particularly the blue-coded orders can sometimes be a sensitive issue,” says Erik Mathijssen, Logistical Lead at GKN Fokker Hoogeveen. “If you’ve been focused on keeping the pipeline filled for so many years, refraining from producing when it’s possible to do so can take some getting used to.”

“Thanks to our smart buffers, our customers never have to wait for composite parts nowadays. And there’s no more discussion about priorities. The team leaders know precisely where they stand and are no longer distracted. Things are calm and clear on the factory floor,” comments Mario Wiersema (pictured), Site Manager Logistics at GKN Fokker Hoogeveen. “We’ve reduced the WIP too, and we expect to reduce it even further when we implement Wipcap, which will also factor the current available capacity into the order release decisions.”

Read here Part 1 of the Wheel of Five for Supply Chain Management.