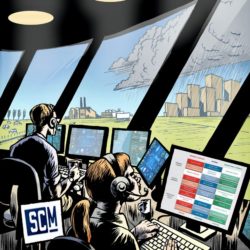

New control tower solutions bring data together

End-to-end supply chain visibility – insight both into interruptions in your suppliers’ supply chains as far afield as Asia and into the actual needs of European consumers – is every supply chain manager’s dream. There have been few real-life examples of success so far, but that now seems to be changing. The latest control tower solutions on the market do more than just show the GPS coordinates of trucks and container ships.

By Marcel te Lindert

Magna, a contract manufacturer based in Graz, Austria, is almost exclusively focused on the upstream supply chain. It produces a total of six different models for three different car makers, but the car manufacturers themselves take care of the downstream supply chain. “All three companies have their own distribution networks but we have no involvement in them, so all our focus is actually on our suppliers,” says Alfons Dachs-Wiesinger, Director Logistics Services at Magna Steyr, which is part of the global mobility and technology company Magna.

A significant number of those suppliers deliver just-in-sequence. The delivery is packed in such a way that the most critical parts can be unloaded first so they are ready for use on the production line in the right order. Hence operators and robots don’t have to sort the parts first; they can simply grab the first component to hand. “Just-in-sequence is an instrument for managing the complexity in the manufacturing process. In the past all bumpers used to be the same, but nowadays we can have hundreds of different versions for each model, with different colours, sensors and cabling for integrated lighting. But just-in-sequence is also an extremely time-critical process. The production order is set in stone. If a truck suffers a tyre blowout or is involved in an accident, we don’t have another trailer loaded with the same components in the same sequence, so visibility is crucially important,” explains Dachs-Wiesinger.

Confusion

Magna Steyr is definitely not the only company to place so much importance on supply chain visibility. According to research by Gartner in 2018, visibility is at the top of the agenda for supply chain professionals – higher even than sales & operations planning, for example – yet the lack of visibility is also one of the biggest headaches for those professionals. In other words, countless companies are investing in visibility, but the adoption still leaves a lot to be desired.

The Magna Steyr example illustrates another relevant point: that visibility differs from one company to another. The contract manufacturer is mainly striving for upstream visibility and isn’t interested in what happens downstream. Martijn Lofvers, founder of Supply Chain Media and publisher of this magazine, has noticed that the term ‘visibility’ can cause considerable confusion: “Many software vendors are capitalizing on companies’ needs with visibility-related solutions. They often claim of offer ‘end-to-end supply chain visibility’ – which means visibility from start to finish, from raw materials to end users. But in practice the visibility often only refers to the section of the supply chain that companies can or want to see, i.e. the part from supplier to customer.” … … …

Want to read more?

Want to read more?

Subscribe to the digital subscription to read the full version >>

or

select one of our annual or digital subscriptions to receive the next issue >>

This article was first published in Supply Chain Movement 35 | Q4 – 2019