Managementarticle: The path to logistics partnerships

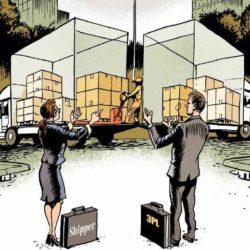

For many companies it’s a recurring question: which logistics processes should they outsource, and which should they handle themselves? Is price the only thing that counts, or does a logistics service supplier’s added value matter too? The online tool called Supply Chain Satellite provides insight into logistics outsourcing strategies. The key conclusion is that companies should seek strategic logistics partners.

By Marcel te Lindert

A company that only ships full pallets will find it pretty easy to outsource its logistics; every industrial estate usually has at least one logistics service provider offering that kind of service at a competitive rate. Outsourcing becomes a little trickier when it involves order picking of products which come from multiple suppliers and have to be adapted in some way before being packed and shipped in line with customer-specific requirements. The service provider’s prices are important, of course, but should price still be regarded as the decisive factor?

The Supply Chain Satellite was launched three years ago to help companies find the right logistics buying strategy for them. This online tool, which is a joint initiative of Supply Chain Media, Nyenrode Business Universeit, DSV Solutions and Districon, is based on the idea that two factors determine the logistics outsourcing strategy: the supply chain complexity and the degree to which the supply chain adds value. These two factors form the axes of a matrix that shows the ideal strategy.

If the supply chain has limited complexity and limited added value, the company will find itself in the bottom-left quadrant among the ‘price buyers’ whose key objective is to maintain a tight grip on costs. Their operation fits perfectly in a standard multi-user warehouse. Companies in the top-right quadrant (‘strategic buyer’) have a greater need for a strategic partner: a logistics service provider that will collaborate with them on the continuous improvement of service levels, delivery options, lead times, efficiency and, ultimately, cost reduction. Companies with broad portfolios of products, suppliers and customers will end up in the top-left quadrant. These are ‘expertise buyers’ for whom it only makes sense to outsource if the logistics service provider can perform certain processes better or more efficiently. Sometimes, outsourcing is simply not a good idea, such as for companies that are placed in the bottomright quadrant. They have such specialized requirements in terms of goods handling and shipment that they are better off developing the necessary logistics competencies themselves. These are the ‘do-ityourselfers’.

Recommended strategy

Supply Chain Satellite clearly meets a need, as the tool is already being used by 1,600 supply chain professionals worldwide The tool’s results are not only valuable for the users themselves, but also for academics conducting research into logistics outsourcing. “The results give us greater insight into how many companies are currently working with the optimal outsourcing strategy,” says Jack van der Veen, professor of supply chain management at Nyenrode Business Universeit. Interestingly, the tool provides insight into both the existing and the recommended strategy. In an exercise in self-reflection, users are first asked to indicate which type of logistics buyer they think they are. Next, they complete a questionnaire which allows detailed analysis of their specific supply chain characteristics. A scientifically based scoring and weighting model then produces tailor-made advice.

… … … … …

Read the full article in Supply Chain Movement 26 | Q3 – 2017