Better planning makes companies more agile

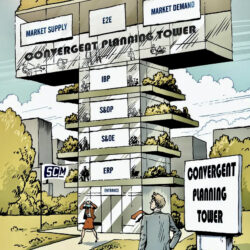

Companies with better planning score better on agility and are performing better during the current pandemic. But better planning first requires a horizontal, integrated planning process that shows how changes in supply or demand affect the supply chain. It also calls for a vertical, internal planning process that links long-term planning to day-to-day operational planning. And then at some point, the horizontal and vertical planning must converge.

By Marcel te Lindert

When large parts of Europe went into lockdown in March 2020, professional painters and decorators were no longer allowed to work indoors. As a result, the demand for paint in the professional sales channel plummeted. Simultaneously, the demand for paint in the DIY channel exploded because consumers were stuck at home anyhow, so they decided to have a go themselves. “That was the case in some countries, at least. In other countries, governments ordered DIY stores to close,” says Filip Buytaert, Director Global of IBP & End-To-End Supply Chain Center Of Excellence at chemical company and paint manufacturer AkzoNobel. “The longer-term trend was positive, though. People spent more money on their homes, and therefore also on paint, and the professional channel has ultimately benefited from that too.”

AkzoNobel also saw erratic demand patterns emerge in other sectors. For example, as the number of car repairs decreased, so too did the demand for automotive paints. Many projects were put on hold in the oil and gas industry, which also led to a drop in demand. “We saw the same thing happen in the boat industry, albeit with the exception of the recreational channel. It was certainly a dynamic year, especially in terms of volatility. Virtually every market segment was hit, but overall we weathered the year reasonably well,” continues Buytaert.

Rituals

Although AkzoNobel saw its sales decline in 2020, it still met its original targets relating to operating profit. According to Buytaert, this was largely thanks to the implementation of integrated business planning (IBP), which the company had initiated in 2018. In early 2019, Buytaert was brought in to give the project a boost. “Until then, implementation had been too much a ‘supply chain-only’ matter. But IBP requires support from throughout the entire company; it’s essential to involve the sales and finance disciplines. That’s why we appointed a commercial colleague as IBP leader in each of the eight business units. We’ve also set up a strong demand management organization made up of demand managers and demand planners for all 54 commercial departments.”

Buytaert purposefully focused on creating new rituals. For example, the demand plan is determined for each business unit on the fifth working day of every month. The management team of each business unit unfailingly meets on the twelfth working day to align the supply plan with the demand plan and to close any gaps. Last but not least, the board meeting is held at the end of every month. “By that time, it’s clear how the supply and demand plan will impact on the financial plan. This meeting is also where decisions are made about problems that the business units can’t solve alone.”

The IBP process rituals are set in stone. Each meeting is scheduled a year in advance and lasts a maximum of two hours. Skipping a meeting or a step in the process is not an option. “Keeping the pace so high means that we make decisions faster. That definitely helped us during the pandemic.” … … …

Want to read more?

Want to read more?

Subscribe to the digital subscription to read the full version >>

or

This article was first published in Supply Chain Movement 41 | Q2 – 2021